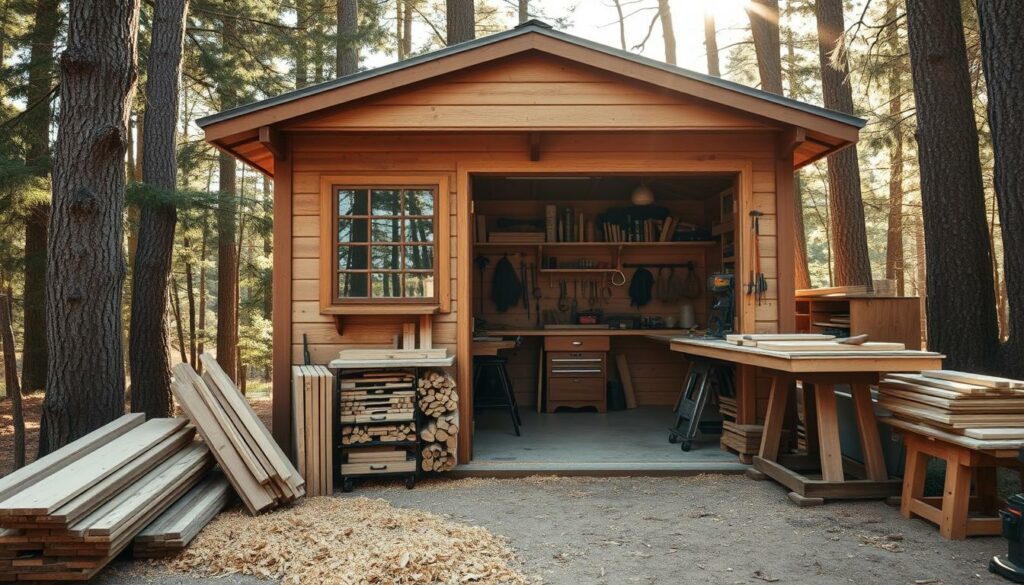

Creating my own woodworking shed was more than building a structure. It was about making a space that shows my love for making things. Every time I used a saw or hammer, it was a step in my woodworking journey. This journey needs hard work and a special place to grow.

This guide is for anyone who wants to build their own woodworking haven. It offers tips on DIY shed plans, designs, and outdoor workshop ideas. These can turn dreams into real spaces.

With MyShedPlans, we have over 12,000 shed plans to choose from. Each plan comes with a list of materials, helping us stay on budget and vision1. The 3D CAD drawings make it easy to see our design from all sides1.

Building a woodworking shed is all about the details. With plans for all sizes, from small storage to big workshops, it’s possible to build one for under $5001.

Key Takeaways

- Building a woodworking shed enables creativity and effective project management.

- MyShedPlans offers a wealth of options with over 12,000 shed plans.

- Material lists provided help in budgeting and planning for your project.

- 3D CAD drawings can assist in visualizing unique designs.

- Affordable plans make it possible to construct a shed for under $500.

Understanding the Purpose of Your Woodworking Shed

A woodworking shed is key for anyone who loves woodworking. These spaces can be simple storage facilities or full workshops. Knowing the different types helps choose the right one.

Types of Woodworking Sheds

There are many types of sheds for woodworking. You can pick from:

- Storage Sheds: Great for organizing tools and materials.

- Workshop Sheds: Have workbenches, machines, and lots of space for projects.

- Hybrid Sheds: Mix storage and workspace for the best of both.

Woodworkers often move to a shed as they grow. It’s a good move when the garage or basement can’t hold everything2. Picking the right shed ensures it meets your woodworking needs.

Benefits of Having a Dedicated Space

A woodworking shed brings many benefits of outdoor storage solutions. It boosts productivity and keeps things organized. It also keeps tools safe from kids, giving you peace of mind2.

Moreover, a shed can increase your home’s value. Sheds cost around $9,000 on average, which is cheaper than a garage or extension3.

It also lets you customize lighting, tool storage, and workspace. This makes your woodworking area efficient and comfortable4.

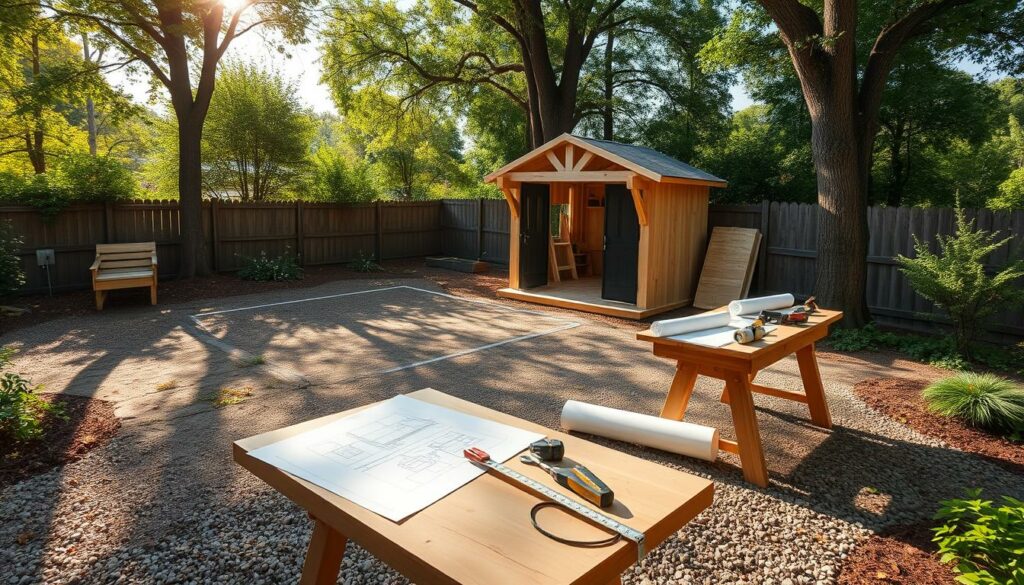

Essential Considerations Before Building

Before starting my woodworking shed project, I thought a lot about local rules and permits. It’s key to check local building regulations because they differ a lot. Some places let you build small structures without a permit, while others have strict rules.

I found out that the size of my shed might not need a permit, depending on its size and local rules. It’s crucial to check for any restrictions before you start building. This can save you a lot of trouble later.

>> Get Instant Access to 12.000 Shed Plans

Local Regulations and Permits

Before I started digging, I made sure I wouldn’t hit any underground lines. I called 811 to mark where the lines were. Following local rules helps protect my investment and keeps me calm while building my shed.

Design and Budget Planning

Once I knew I followed local building regulations, I focused on a solid design and budget. A good shed construction guide helped me figure out what materials I need and how much they cost. I looked at different foundation options, like using 6x6s with gravel or a concrete slab.

Both options are durable, and a raised foundation helps avoid rot and shifts from soil erosion5. My design makes the most of the space and is built to last.

I made a table to compare materials based on cost, durability, and how easy they are to install. My careful planning helped me avoid waste by choosing standard sizes for my shed. This kept my budget in check without sacrificing quality.

| Material | Cost ($) | Durability | Installation Difficulty |

|---|---|---|---|

| CDX Plywood | 25 | Moderate | Medium |

| OSB | 20 | High | Medium |

| Metal Roofing Panels | 30 | High | High |

| Concrete Slab | 50 | Very High | High |

Good planning for design and budget makes building a shed smooth and ensures I follow local rules56.

>> Get Instant Access to 12.000 Shed Plans

Choosing the Right Location for Your Shed

When I started my woodworking shed project, picking the right spot was key. It affects how easy it is to get to, how visible it is, and how well it works. I realized that knowing my yard’s shape was crucial.

Flat ground is best for building because it’s stable and makes setup easier. Avoiding roots or rocks is important to prevent construction problems7. Also, a slight slope is needed for water to run off, especially for concrete foundations7.

Assessing Your Yard’s Topography

Low spots that collect water can cause wood damage and mold. It’s important to avoid these areas7. I also made sure my shed was far from branches that could scratch or break in storms7.

While trees near the shed might look nice, young ones could grow too big. This might mean you’ll need to move the shed later.

Shed Visibility and Accessibility

Accessibility was a big deal for me. I picked a spot that’s easy to see from my house8. This makes it easier to watch the shed and what’s inside8.

Having it visible also helps with security. I thought about adding lights and strong locks. This is because my shed will have valuable tools and materials. It’s also important to have easy access for moving things in and out, and space for ramps if needed8.

Materials & Tools You Will Need

Building a woodworking shed needs careful planning. You must choose the right materials and tools. This ensures your shed is strong and lasts long.

>> Get Instant Access to 12.000 Shed Plans

Essential Materials Guidelines

For my shed, I choose materials that are strong and reliable. Pressure-treated lumber is key, especially for the floor. Here, 2 x 8s are used for the edges.

Joists are spaced 16 inches apart. This gives the shed great support and helps it carry weight evenly.

Other important materials include:

- Oriented strand board (OSB) for sheathing

- Shingles for roofing

- 8d ring shank nails for siding attachment

- Aluminum drip edge for roof edges

- Plywood gussets to connect rafters effectively

Using these essential materials helps build a strong shed. It keeps the shed safe from the weather and stays solid over time9.

Tools Required for Shed Construction

Having the right tools is just as important. I focus on basic tools that make the job easier and more precise:

| Tool | Purpose | Recommended Brands |

|---|---|---|

| Table Saw | Versatile cutting of wood | DeWalt, SawStop |

| Bandsaw | Cutting thin veneers and curves | Jet, Laguna |

| Orbital Sander | Sanding surfaces smoothly | Makita, Bosch |

| Drill | Boring holes and driving screws | Milwaukee, Ryobi |

| Circular Saw | Accurate cuts on larger sheets | Makita, Ryobi |

| Jointer | Creating flat, square edges | Grizzly, Powermatic |

| Planer | Thicknessing lumber | Jet, DeWalt |

| Miter Saw | Crosscutting at angles | Bosch, DeWalt |

| Chisels | Detailed woodwork | Stanley, Narex |

| Dust Collector | Maintaining cleanliness | Grizzly, Shop Fox |

I build my tool collection over time, choosing quality tools. The table saw is very versatile. An orbital sander is great for sanding, and a jointer is key for square joints. Investing in good brands makes building the shed better1011.

>> Get Instant Access to 12.000 Shed Plans

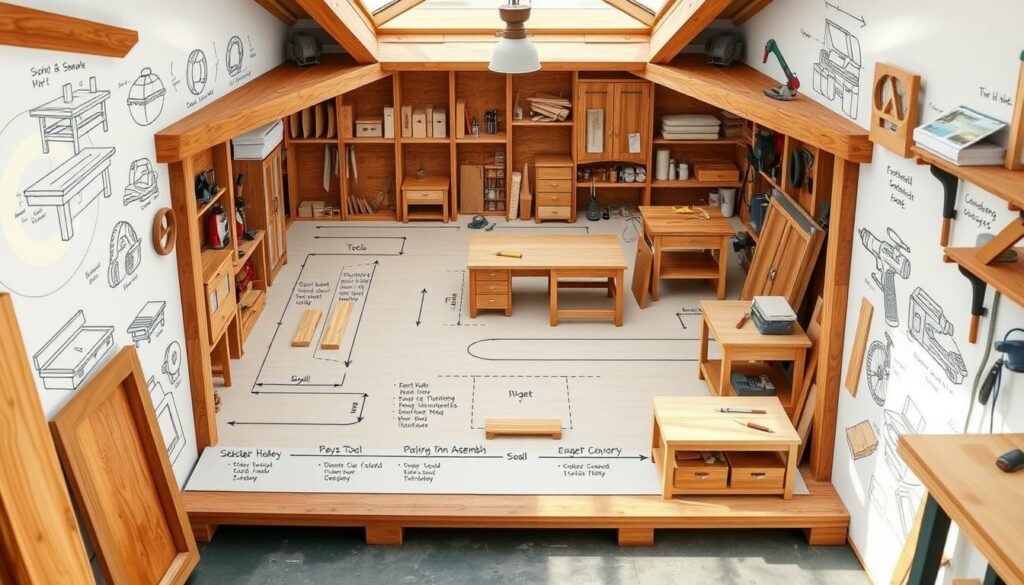

Planning Your Woodworking Shed Layout

A good layout makes my woodworking shed more efficient. When planning, I focus on tool placement, workspaces, and storage. This setup helps me work better and use space wisely for all projects.

Floor Plan Considerations

Designing the floor plan is key. I aim for at least 75 square feet for tools, but 125 square feet is better12. Tools should be 3 feet apart for easy use. Using rolling bases saves space too.

Sorting tools by how often I use them helps a lot13. A stable, spacious woodworking bench is also important. It keeps me safe and efficient.

>> Get Instant Access to 12.000 Shed Plans

Designing with Storage in Mind

Good storage keeps my workspace tidy and efficient. Vertical storage and wall racks are great for small spaces. Mobile carts for tools make access easy and flexible.

Good lighting is crucial; I use task lights or LED strips for precision13. An air filter and dust extractor keep the air clean and flowing13. Adding safety features like ergonomic designs and easy safety access makes the layout even better.

How to Build a Solid Foundation

Building a solid foundation is key for your woodworking shed. It ensures stability and durability over time. There are various foundation types for different ground conditions. This helps your shed stay level and functional for years.

Understanding these options helps you choose the right one for your needs. This makes the foundation a crucial part of your shed construction guide.

>> Get Instant Access to 12.000 Shed Plans

Types of Foundations for Various Ground Conditions

There are several foundation types, each for different environments:

- On-grade Foundation: Ideal for sheds up to 160 sq ft.

- Permanent Foundation: Involves concrete slab or piers for longer-term setups.

- Concrete Block Foundations: Uses 4-inch thick x 8-inch wide x 16 inches long blocks for on-grade foundations14.

- Skid Foundations: Have been used for over 300 years to support various outdoor buildings14.

- Monolithic Concrete Slabs: Are 8 to 12 inches thick for walls and 4 to 6 inches thick for floors14.

- Floating-Slab Foundations: Have a 4 to 6-inch thick layer of concrete directly on the groun

>> Get Instant Access to 12.000 Shed Plans

Using Deck Blocks vs. Concrete Slabs

Choosing between deck blocks and concrete slabs depends on the ground and your budget. Deck blocks are easy to install and adjust for uneven surfaces, great for my backyard. Concrete slabs, however, offer a solid, permanent base that resists moisture, ideal for larger sheds14.

Using treated wood frames filled with gravel is another option. It’s good for firm soil and flat ground, keeping costs down15.

Framing Your Woodworking Shed

Framing is key as it’s the backbone of my woodworking shed. I chose 2×6 framing for extra strength. This is because I plan to insulate it and add heating and air conditioning. My shed is 15′ x 15′ with 9′ ceilings and a loft for wood storage.

Following shed framing tips, I spaced studs for strength while keeping costs down. Screws are better than nails for easy adjustments without weakening the structure. I also plan to add windows, including two 3’x5′ windows and a smaller one on the fourth wall, with more above the door16. I bought used double-pane insulated windows locally for $10016.

Best Practices for Wall and Roof Framing

Building walls with 15′ x 10′ 2×6 framing is heavy and needs help. I used a truss calculator for the roof, saving time and effort. Marking boards with templates was quick, taking just 11 minutes for 24 boards16.

Constructing my shed has been safe, with only minor foot bruises16. The materials cost about $325, including pressure-treated parts17. While one person can build it, having help is helpful for tasks like measuring and leveling.

Following the construction guide ensures stability with the right screws17. This focus on detail makes my shed durable and functional.

>> Get Instant Access to 12.000 Shed Plans

| Feature | Details |

|---|---|

| Size | 15′ x 15′ |

| Ceiling Height | 9′ |

| Framing Type | 2×6 |

| Windows | Multiple: 3’x5′ on two walls, smaller on one wall, and a row above the door |

| Insulation | Intended for heating and A/C |

| Cost of Windows | $100 for used double-pane insulated windows |

| Materials Cost | Approximately $325 |

| Construction Time | One day with recommended assistance |

Constructing the Roof: Tips and Techniques

Choosing the right roofing materials is key for my woodworking shed’s durability and function. A solid roof keeps the structure safe from the weather and lasts longer. Each roofing option has its own benefits and features, depending on what I need and like.

Types of Roofing Materials

I have many roofing material choices, each with different costs, lifespans, and upkeep needs:

- Asphalt shingles: Cost between $1-3 per square foot installed, they are a popular choice for their affordability and ease of installation. Three-tab shingles often come with warranties lasting up to 30 years18.

- Metal roofing: Ranging from $3-6 per square foot installed, metal roofs are known for their longevity, with warranties often exceeding 50 years18.

- Roll roofing: Available at about $1 per square foot, this material lasts 10-15 years and is suitable for low-slope roofs18.

- Wood shingles: Priced at $3-9 per square foot, these can last over 30 years with proper maintenance18. Cedar shakes can last up to 35 years when maintained adequately19.

A 3:12 pitch is the minimum roof slope recommended, with a 7:12 pitch being common for shed roofs18. This ensures water flows off properly.

>> Get Instant Access to 12.000 Shed Plans

Knowing the roof slope types—flat, low, medium, and steep—helps estimate material needs accurately20. Roofing materials are sold by the square, so I should add 10-15% for waste. When working at heights, I must use protective gear and ensure ladders are stable20.

By following these tips, my woodworking shed will be more resilient and functional. It will also meet safety standards182019.

Interior Organization for Your Woodworking Shed

Keeping your woodworking shed organized is key to getting the most out of it. A well-organized shed lets you work on projects smoothly, without clutter. This makes your projects more enjoyable and efficient.

Efficient Storage Solutions

Using adjustable organization systems is a smart move. They let you change your setup as needed. I found 27 budget-friendly ways to organize tools, making it easy to start21.

I tackle one area at a time to avoid feeling overwhelmed. This helps me keep my shed tidy and organized.

For example, I use twin slot shelves and laminate worktops for my workbenches. Storing less-used items in lofts saves space21. Movable storage with castor wheels makes it easy to move tools around.

>> Get Instant Access to 12.000 Shed Plans

Creating Work Zones

Setting up different work zones in your shed helps you stay focused. My shed is 6 by 8 feet, so I use every inch wisely22. I have two worktables, one big and one small, which can be moved together22.

I’ve made tool holders and racks from scraps and basic materials. I even built a platform with castor wheels for my vacuum. This makes cleaning up after messy projects a breeze. I also use cardboard boxes for sandpaper and a DIY holder for caulk tubes21.

Custom Shed Designs for Your Unique Needs

Creating a woodworking shed that fits my needs means going for custom designs. These designs let me make a space that’s perfect for me. It meets my storage needs and looks the way I want it to.

>> Get Instant Access to 12.000 Shed Plans

Incorporating Windows and Vents

Windows and vents are key in my woodworking shed. Windows let in natural light, making it easier to see what I’m doing. Vents keep the air moving, so the shed doesn’t get too hot or stuffy.

Choosing where to put these features makes my shed more comfortable and useful. B&L Woodworking says I can pick materials for my windows to keep them strong and good-looking23. Adding skylights can make the inside even brighter.

Building Specialty Features

I can also add special features to my shed. This could be shelves for tools or a workbench made just for my projects. B&L Woodworking has different shed styles, like A-frame and barn-style, that can have built-in cabinets23.

Features made just for my woodworking can make my space more organized and creative.

Using DIY shed plans lets me make a space that’s just right for me. A custom-built woodworking shed is more than just storage. It’s a special place for my projects and hobbies24.

>> Get Instant Access to 12.000 Shed Plans

Conclusion

Building your own woodworking shed is a goal you can reach. It can turn your outdoor area into a workshop that’s all your own. This guide has covered everything from rules to materials and design. You now have all the tools and knowledge you need.

Choosing the right size, like a 12×16 shed, gives you about 162.84 ft² of space. This space is perfect for storing things like fuel cans, garden tools, and even a small car25.

Remember, a good shed needs strong materials. Using pressure-treated lumber makes your shed last longer, even in bad weather26. With careful planning, you can make a workspace that boosts your creativity and keeps your tools organized.

Whether you build it yourself or buy one, the journey is rewarding. The cost can be high, up to $7,571.14 for a DIY build25. But, a woodworking shed shows your commitment to your craft and boosts your productivity.

>> Get Instant Access to 12.000 Shed Plans

FAQ

What are the benefits of having a woodworking shed?

Do I need a permit to build a woodworking shed?

What materials do I need to build a woodworking shed?

How should I organize the interior of my woodworking shed?

What type of foundation is best for a woodworking shed?

Can I personalize my woodworking shed design?

What roofing materials are recommended for a woodworking shed?

Source Links

- My Honest Review of MyShedPlans: A Complete Guide to Building Your Own Shed – https://www.linkedin.com/pulse/my-honest-review-myshedplans-complete-guide-building-your-brown-95lae

- Six Most Essential Elements of Any Woodworking Space | Newmart Builders – https://www.newmartbuildersinc.com/blog/six-most-essential-elements-of-any-woodworking-space/

- Put a Shop in a Shed – FineWoodworking – https://www.finewoodworking.com/2014/10/22/put-a-shop-in-a-shed?srsltid=AfmBOorhSC8gd_S3y3G-bDLKMmpM1gUq3WH_VqQYvpRp4nOAqXwI3oTO

- No title found – https://mwawoodworks.com/woodworking-shop-layout/

- 13 Tips for Building a Shed – https://www.familyhandyman.com/list/diy-storage-shed-building-tips/?srsltid=AfmBOopJgX6J2VWlshsHs0uFMDn1lFLVwYfctXKoDirMEqTcaaU8JvRI

- Things to Consider When Building a Shed – Parr Lumber – https://parr.com/blog/things-to-consider-when-building-a-shed/

- How To Choose Your Storage Shed Location – 8 Useful Tips – https://www.siteprep.com/articles/storage-shed-location/

- Shed Placement – How to Choose the Best Location – https://www.urban-sheds.com/post/shed-location-and-placement

- 10 Essential Woodworking Tools To Start Your Shop — Blacktail Studio – https://www.blacktailstudio.com/blog/essential-woodworking-tools

- How to Build a Shed – https://www.homedepot.com/c/ah/how-to-build-a-shed/9ba683603be9fa5395fab90434412ca

- Different Shed Building Materials and How to Choose the Best One – https://www.urban-sheds.com/post/shed-building-materials

- Setting Up a Workshop – https://www.instructables.com/Setting-Up-a-Workshop/

- Optimize Your Small Wood Shop Layout For Maximum Production – https://toolstoday.com/learn/how-to-layout-a-small-wood-shop?srsltid=AfmBOoo178bc8ntjHqjXxs0FN9zGENsYa4EVTDOJdvWF7QLSDHGgD3ca

- Shed foundation – https://shedplans.org/shed-foundation/

- How to build a shed foundation – https://solidbuildwood.com/how-to-build-a-shed-foundation/?srsltid=AfmBOooDx3mlsvDGhvgSSXTIJ0i36TTN8S51YbDbSMuY_DJ9w003a25G

- Building a Wood Shop from Scratch – Framing Progress – LRN2DIY – https://lrn2diy.com/building-a-wood-shop-from-scratch-framing-progress/

- PDF – https://www.fnsb.gov/DocumentCenter/View/1210/How-To-Build-A-Wood-Shed-PDF

- Shed Roof Framing – https://shedplans.org/shed-roof-framing/

- How to Felt a Shed Roof + Tips & Tricks – https://thecarpentersdaughter.co.uk/woodworking/felt-shed-roof-installation/

- How to Build a Shed Roof? | Stronghold Roofing & Solar – https://strongholdroofing.com/blog/how-to-build-a-shed-roof/

- 27 Organizing a Shed Ideas For Workshop Tools – https://thecarpentersdaughter.co.uk/woodworking/organizing-a-shed/

- Organize workshop she shed interiors – Country Design Style – https://countrydesignstyle.com/she-shed-interiors/

- Custom Shed Options | Designing Your Shed [Step-by-Step Guide] – https://www.blwoodwork.com/blog/custom-shed-options

- 12 Custom Shed Ideas | Gold Star Buldings – https://www.goldstarbuildings.com/prefab-sheds-ideas/12-custom-shed-ideas/

- 12×16 Sheds | Answering Your Top 5 Questions – https://5starbuildings.com/news-stories/12×16-shed-questions-answered/

- DIY Firewood Storage: How to Build a Wood Shed – https://www.woodsmith.com/review/how-to-build-a-wood-shed/